Manual Turning since 1988

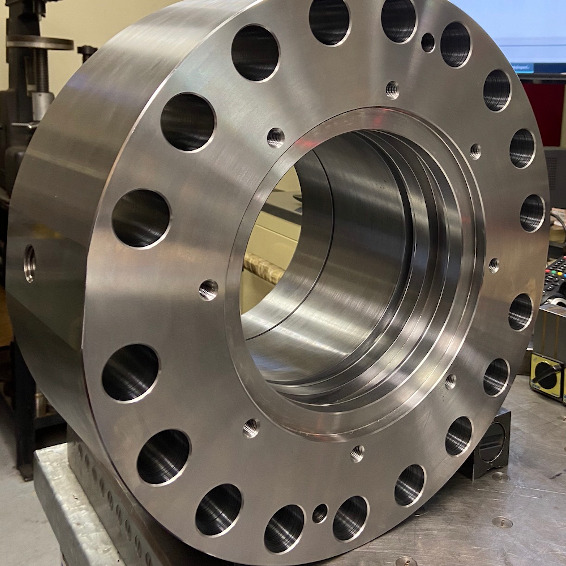

Our team of highly skilled and experienced machinists are experts in producing high-quality, accurate milling of bar stock, castings, forgings, and fabrications in both ferrous and nonferrous materials and plastics.

Manual Turning

Our highly skilled machine operators are experienced in machining most grades and types of materials. They are familiar with machining billets, castings, forgings, and fabrications. In addition, we use the latest cutting tool technology, ensuring components meet our clients' specifications.

In addition, we understand the importance of cost-effectiveness, especially for one-off machining and small-quantity batch sizes.

Some of the types of work our team have machined include the following:-

- Axels

- Bearing Retainers

- Bushes

- Celvis Pins

- Celvises

- Couplings

- Cylinder Tubes

- Duo Cones

- End plates

- Flanges

- Guages

- Glands

- Housings

- Hubs

- Hydraulic Cylinder Rods

- Impellors

- Nuts

- Pins

- Pistons

- Precision Shafts

- Shafts

- Sheaves

- Sleeves

- Spacers

- Special bolts

- Special fittings

- Special studs

- spherical housing

- Taper Hubs

- Tapered pins

- Washers

- Wheels

Hillier Engineering Services' manual turning services can provide one-offs and small batch sizes. In addition, every lathe is fitted with digital readouts and high-precision measuring equipment, ensuring consistent quality.

If you require Manual Turning Services, contact us and experience the difference in precision, quality, and service.